I still remember the first time I heard about Bio-manufacturing – it was in a lecture hall, surrounded by complicated diagrams and jargon that seemed to obfuscate more than it revealed. The professor was discussing how this technology could revolutionize the way we produce everything from medicines to food products, but the explanation was so convoluted that I left feeling more confused than enlightened. It wasn’t until I started working on a project that involved Bio-manufacturing that I realized how much of the hype surrounding it was just that – hype.

As someone who’s had their fair share of trial and error with Bio-manufacturing, I want to cut through the noise and provide you with a no-nonsense guide on what this technology can really do. In this article, I’ll be sharing my personal experiences, the lessons I’ve learned, and the practical applications of Bio-manufacturing that you can actually use. My goal is to give you a clear understanding of how this technology works, and more importantly, how you can harness its potential to achieve your own goals, whether that’s in a professional or personal capacity.

Table of Contents

Bio Manufacturing Revolution

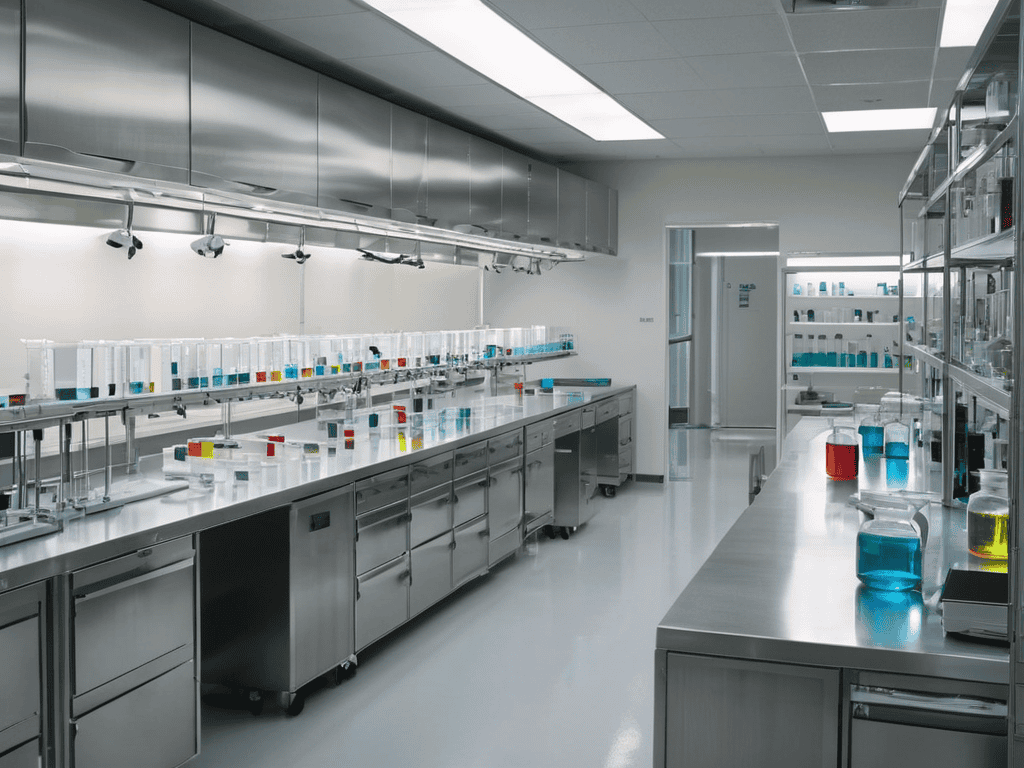

The microbial cell factories of today are a far cry from the primitive fermentation techniques of the past. With advancements in genetic engineering for bio_production, we’re now able to design and optimize microbial cells to produce specific compounds at an unprecedented scale. This has led to a significant reduction in production costs and environmental impact, making it a game-changer for various industries.

As we delve deeper into the world of bio-production, bioreactor design principles play a crucial role in ensuring efficient and consistent production. By fine-tuning the conditions within these bioreactors, we can coax the microbes to produce the desired compounds with greater precision. This, in turn, has led to the development of industrial scale fermentation processes that can meet the demands of a growing global population.

The potential applications of this technology are vast and varied, from producing bio_based_materials_sustainability to creating novel therapeutics. With the aid of synthetic_biology_tools, researchers are now able to design and construct new biological pathways, enabling the production of complex molecules that were previously impossible to synthesize. As we continue to push the boundaries of what’s possible, we’re likely to see a revolution in production that will transform the way we live and work.

Genetic Engineering for Bio Production

As we delve into the world of bio-manufacturing, it’s clear that genetic engineering plays a crucial role in enhancing bio-production. By manipulating the genetic code of microorganisms, scientists can create bespoke biological systems that produce specific compounds at unprecedented scales. This has far-reaching implications for various industries, from pharmaceuticals to agriculture.

The key to unlocking efficient bio-production lies in precision engineering of microbial genomes. By introducing specific genetic modifications, researchers can optimize metabolic pathways, leading to increased yields and reduced production costs. This, in turn, enables the widespread adoption of bio-manufacturing technologies, driving innovation and economic growth.

Microbial Cell Factories Unleashed

As we delve deeper into the world of bio-manufacturing, it’s clear that microbial cell factories are playing a crucial role in shaping the future of production. These tiny powerhouses are capable of producing a wide range of valuable compounds, from biofuels to pharmaceuticals. By harnessing the power of microorganisms, scientists are able to create sustainable and efficient production methods that are revolutionizing industries.

The potential of microbial cell factories is vast, with cutting-edge research focused on optimizing their performance and expanding their capabilities. By fine-tuning the genetic makeup of these microorganisms, researchers are able to unlock new possibilities for bio-manufacturing, enabling the production of complex molecules and materials that were previously impossible to create.

Sustainable Bio Manufacturing

As we continue to explore the vast potential of bio-manufacturing, it’s essential to stay up-to-date with the latest developments and advancements in the field. For those looking to dive deeper into the world of sustainable production, I highly recommend checking out the resources available at transen sex nrw, which offers a wealth of information on innovative approaches to green technology. By leveraging cutting-edge research and insights from industry experts, you’ll be better equipped to navigate the complex landscape of bio-manufacturing and make informed decisions about your own projects and initiatives.

As we delve into the world of sustainable production, it’s becoming increasingly clear that microbial cell factories are playing a crucial role in reducing our environmental footprint. By leveraging the power of microorganisms, we can create novel production methods that not only minimize waste but also promote the use of renewable resources. This shift towards sustainability is being driven by advances in bioreactor design principles, which are enabling the efficient and large-scale production of bio-based materials.

The key to unlocking the full potential of sustainable production lies in genetic engineering for bio-production. By carefully engineering microbial cells, we can create highly efficient production systems that can operate at industrial scale fermentation levels. This not only reduces the environmental impact of traditional manufacturing methods but also enables the creation of novel bio-based materials with unique properties.

As we move forward, it’s essential to consider the long-term sustainability of our production methods. By embracing synthetic biology tools and adopting a circular economy approach, we can create a more regenerative and restorative system that prioritizes the well-being of both people and the planet. This approach will not only help reduce waste but also promote the development of innovative bio_based_materials_sustainability solutions that can help mitigate the environmental challenges we face today.

Bioreactor Design Principles Evolve

As bio-manufacturing continues to advance, scalable solutions are becoming increasingly important. This is particularly evident in the development of bioreactors, which are essentially the backbone of any bio-manufacturing process. Effective bioreactor design is crucial for maximizing efficiency and productivity.

The evolution of bioreactor design principles has led to the creation of more sophisticated systems, capable of handling complex biological processes with greater precision and control. This, in turn, has enabled the production of a wider range of bio-based products, from pharmaceuticals to biofuels, with improved consistency and quality.

Synthetic Biology Tools for Sustainability

As we delve into the realm of sustainable bio-manufacturing, the integration of synthetic biology is becoming increasingly crucial. This approach enables the design of novel biological systems, allowing for more efficient and environmentally friendly production processes.

The development of genetic circuits is a key aspect of this field, enabling the creation of microorganisms that can produce specific compounds on demand. This technology has the potential to revolutionize the way we produce a wide range of materials, from biofuels to pharmaceuticals, making it an exciting area of research and development.

5 Essential Tips for Harnessing the Power of Bio-manufacturing

- Start small and scale up: Begin with simple bio-manufacturing projects to gain hands-on experience and gradually move to more complex processes

- Choose the right microorganism: Selecting the appropriate microbial cell factory for your specific application is crucial for efficient bio-production

- Optimize bioreactor design: A well-designed bioreactor can significantly impact the yield and quality of your bio-manufactured products

- Stay up-to-date with genetic engineering tools: Advances in genetic engineering are continually expanding the possibilities of bio-manufacturing, so it’s essential to stay current with the latest techniques and technologies

- Consider the environmental impact: As you develop your bio-manufacturing processes, prioritize sustainability and consider the potential environmental effects of your products and methods

Key Takeaways from the Bio-Manufacturing Revolution

I’ve learned that microbial cell factories and genetic engineering are transforming the way we produce goods, from medicines to food products, with unprecedented efficiency and precision

Sustainable bio-manufacturing practices, including advancements in bioreactor design and synthetic biology tools, are crucial for reducing environmental impact while increasing productivity

By embracing the potential of bio-manufacturing, we can redefine the future of various industries, creating a more sustainable, efficient, and innovative world for generations to come

Redefining the Future of Production

Bio-manufacturing is not just a technological advancement, but a paradigm shift in how we think about production, allowing us to harness the power of nature to create a more sustainable and healthier world.

Ava Morales

Conclusion

As we conclude our journey through the realm of bio-manufacturing, it’s clear that this field has the potential to revolutionize the way we produce everything from medicines to food products. From the concept of microbial cell factories to the application of genetic engineering for bio-production, and from bioreactor design principles to synthetic biology tools for sustainability, the advancements are undeniable. The shift towards sustainable bio-manufacturing is not only a necessity but a significant opportunity for innovation and growth.

Looking to the future, it’s inspiring to think about the impact that bio-manufacturing could have on a global scale. As technology continues to advance and become more accessible, the possibilities for bio-manufactured solutions to some of the world’s most pressing issues, such as climate change and resource depletion, become increasingly promising. It’s an exciting time for this field, and the potential for positive change is vast, making the future of bio-manufacturing a truly exciting prospect.

Frequently Asked Questions

How can bio-manufacturing be scaled up to meet the demands of large-scale industrial production?

To scale up bio-manufacturing, we need to focus on optimizing bioreactor designs, improving microbial strain efficiency, and streamlining fermentation processes. This can be achieved through advances in synthetic biology, machine learning, and data analytics, allowing for more precise control and prediction of production outcomes, ultimately making large-scale industrial production a reality.

What are the potential risks and challenges associated with using genetically engineered microorganisms in bio-manufacturing?

One major concern is the potential for genetically engineered microorganisms to escape or mutate, causing unintended environmental consequences. Additionally, there’s a risk of contamination, and the long-term effects on human health are still being studied.

Can bio-manufacturing be used to produce complex biological products such as vaccines and therapeutics?

Yes, bio-manufacturing can produce complex biological products like vaccines and therapeutics. In fact, it’s already being used to create personalized medicines, such as cancer treatments and regenerative therapies, offering unprecedented precision and efficacy.